The Return of Forgotten Systems

The re-emergence of fuel infrastructure inside digital campuses marks a subtle but consequential shift in data center design philosophy. Facilities once conceived as purely electrical environments are now absorbing concepts historically associated with industrial energy systems. Storage vessels, controlled fuel handling zones, and combustion-adjacent processes are being reconsidered within environments long optimized for electrons rather than molecules. This change is not driven by nostalgia for legacy infrastructure but by structural constraints facing digital growth. Consequently, design assumptions embedded over decades are being quietly revisited rather than publicly challenged. The resulting transition is reshaping how resilience, autonomy, and continuity are framed in modern digital estates.

The earlier era of data center development emphasized abstraction from physical energy realities. Power was treated as an external service delivered reliably through grids and substations. Mechanical complexity inside campuses was minimized wherever possible to reduce operational exposure. However, as energy vectors diversify, that abstraction is becoming harder to maintain. Hydrogen and low-carbon gas introduce physicality back into digital environments. This presence brings operational considerations that had largely disappeared from mainstream facility discourse.

The Historical Absence of Fuel Systems in Digital Facilities

Data centers did not always exclude fuel-based systems from their internal logic. Early computing facilities relied on on-site generation, often using diesel or gas turbines. Over time, grid reliability improvements allowed these systems to recede into backup roles. Combustion became an emergency function rather than a primary operational concern. As a result, architectural and engineering cultures evolved away from fuel-centric thinking. The separation between IT environments and energy systems hardened into accepted doctrine.

By the late twentieth century, fuel handling was treated as a risk vector rather than an asset. Regulatory scrutiny, safety management, and environmental considerations reinforced this perception. Backup generators were isolated physically and procedurally from core operations. Design playbooks increasingly emphasized electrical redundancy over fuel diversity. This shift aligned with a broader industry preference for modular, repeatable electrical architectures. Fuel infrastructure, therefore, faded from strategic conversations rather than from necessity alone.

Hydrogen as a Catalyst for Reconsideration

Hydrogen’s introduction into data center contexts has altered this long-standing equilibrium. Unlike diesel, hydrogen is not confined to emergency use cases by default. Its properties enable sustained energy delivery under specific conditions. Consequently, fuel handling is no longer an exceptional circumstance. Storage, regulation, and controlled release become continuous design considerations. These requirements place fuel infrastructure inside digital campuses back into strategic scope.

Sources: https://www.energy.gov/eere/fuelcells/hydrogen-and-fuel-cells | https://www.iea.org/reports/global-hydrogen-review

The physical characteristics of hydrogen demand new spatial and procedural frameworks. Lightweight molecules, pressure-based storage, and ventilation requirements differ markedly from legacy fuels. Safety protocols must be embedded into everyday operations rather than reserved for emergencies. This integration challenges established zoning assumptions within campuses. Mechanical and electrical systems must now coexist with chemical management regimes.

Low-Carbon Gas and the Return of Combustion Logic

Low-carbon gas options extend this reconsideration beyond hydrogen alone. Methane-based fuels, when sourced and processed differently, reintroduce combustion without reverting to historical emissions profiles. For digital campuses, this means combustion logic returns under revised environmental framing. Turbines, burners, and heat management systems regain relevance. These systems must now integrate seamlessly with digital operational expectations.

Combustion’s reappearance does not imply regression. Instead, it reflects adaptation to new energy constraints. On-site generation using low-carbon gas enables autonomy under grid stress conditions. However, it also requires expertise long absent from IT-centric operational teams. Training, governance, and maintenance cultures must evolve accordingly. Fuel infrastructure inside digital campuses thus becomes both a technical and organizational challenge.

Fuel storage had largely vanished from primary data center layouts. Tanks existed, but they were peripheral and minimally discussed. Hydrogen and low-carbon gas reverse that marginalization. Storage becomes central to capacity planning and risk modeling. Physical volume, containment integrity, and inspection regimes regain prominence. These considerations reshape site selection and campus expansion strategies.

Unlike electrical storage, fuel storage introduces temporal persistence. Energy exists as matter rather than charge. This distinction affects how resilience is conceptualized. Stored fuel decouples operational continuity from instantaneous grid conditions. However, it also imposes new stewardship responsibilities. The permanence of stored energy demands disciplined oversight rather than passive reliance.

Fuel handling reintroduces human-centric risk vectors into automated environments. Valves, connectors, and transfer procedures require trained intervention. Unlike purely electrical systems, these processes cannot be fully abstracted. Human judgment becomes integral to safety and continuity. This shift challenges the prevailing automation-first ethos of modern data centers.

Operational cultures must adapt to this renewed dependency on procedural rigor. Documentation, drills, and incident response frameworks take on heightened importance. Fuel infrastructure inside digital campuses therefore reshapes workforce requirements. Skills once associated with industrial plants reenter digital facility staffing models. The boundary between IT operations and energy operations becomes increasingly porous.

Spatial Zoning and Campus Geometry

The reintroduction of fuel systems alters how space is allocated within campuses. Safety distances, blast radii, and ventilation corridors impose constraints absent from purely electrical designs. These factors influence building orientation and density. Campus geometry must accommodate both digital efficiency and physical safety. As a result, master planning regains strategic significance.

Zoning decisions also affect future scalability. Fuel infrastructure cannot be relocated as flexibly as modular electrical components. Early design choices therefore carry long-term implications. Digital campuses must balance immediate capacity needs against future adaptability. Fuel presence makes that balance more complex but also more grounded in physical reality.

Fuel systems attract regulatory attention by default. Their presence inside digital campuses increases external visibility. Compliance regimes extend beyond electrical codes into chemical safety and environmental oversight. Governance structures must therefore expand in scope. This expansion introduces new interfaces between operators and authorities.

Regulatory engagement becomes continuous rather than episodic. Inspections, reporting, and audits are embedded into operational rhythms. For organizations accustomed to abstracted energy supply, this visibility represents a cultural adjustment. However, it also reinforces accountability. Fuel infrastructure inside digital campuses thus aligns digital growth with tangible responsibility.

Integration With Electrical Architectures

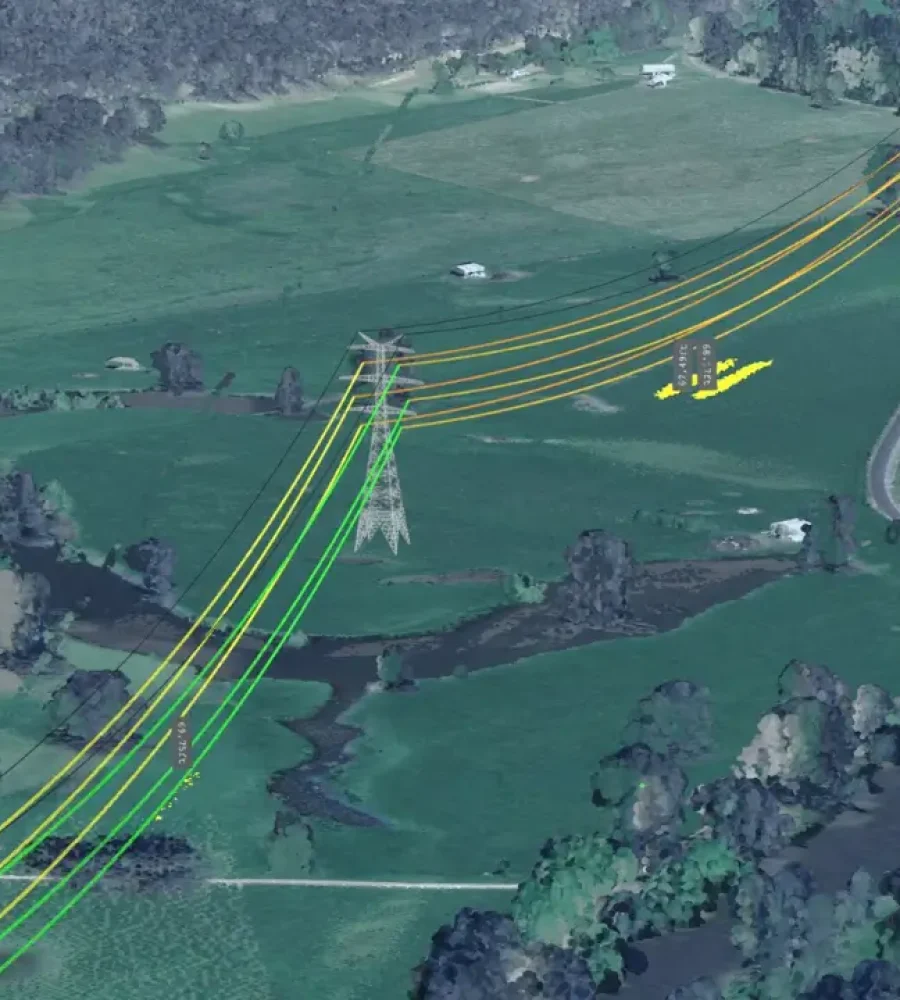

The coexistence of fuel systems and electrical infrastructure requires careful orchestration rather than simple adjacency. Power electronics, switchgear, and control systems must interpret energy delivered through fundamentally different physical pathways. Coordination between chemical energy conversion and electrical distribution introduces layered complexity. Control logic must synchronize generation, storage, and load management without privileging one vector over another. This integration reshapes how reliability is engineered rather than merely specified.

Electrical architectures historically prioritized predictability and uniformity. Fuel-based inputs disrupt those assumptions by introducing dynamic physical states. Pressure, temperature, and flow conditions become relevant variables alongside voltage and frequency. Monitoring systems must therefore expand their sensing scope. The convergence of these domains demands interdisciplinary engineering approaches that were previously unnecessary within digital campuses.

Control Systems and Operational Visibility

Fuel infrastructure cannot operate as a blind subsystem within digital campuses. Continuous visibility into storage levels, flow integrity, and safety conditions is mandatory. Control systems must translate physical fuel states into actionable operational intelligence. This requirement elevates the role of supervisory platforms. Data becomes a bridge between chemical processes and digital decision-making.

Sources: https://www.iso.org/standard/71560.html | https://www.ieee.org/

Operational visibility also alters incident response dynamics. Alerts related to fuel systems carry different urgency profiles than electrical faults. Decision-making timelines may compress or expand depending on physical behavior. Operators must interpret signals that do not conform to familiar electrical failure modes. Training and simulation become essential tools for maintaining situational awareness.

Safety Frameworks Reenter the Foreground

Safety considerations dominate discussions of fuel infrastructure inside digital campuses. Unlike electrical hazards, fuel-related risks extend beyond immediate equipment boundaries. Flammability, dispersion, and containment failure scenarios require holistic mitigation strategies. Safety frameworks must therefore encompass entire campuses rather than isolated rooms. This expansion influences both design and daily operations.

Procedural discipline becomes as important as technical safeguards. Checklists, redundancies, and interlocks must be enforced consistently. Human error carries amplified consequences in fuel-handling contexts. As a result, safety culture cannot remain implicit. It must be articulated, rehearsed, and audited with rigor comparable to industrial energy facilities.

Fuel presence alters how digital campuses interact with their surrounding environments. Ventilation pathways, exhaust management, and buffer zones shape external footprints. Site selection criteria must incorporate these considerations early. Locations once deemed suitable based solely on electrical access may require reassessment. Environmental interfaces thus become strategic variables rather than peripheral concerns.

Community perception also plays a role in this recalibration. Fuel storage and combustion evoke industrial imagery that digital campuses had largely escaped. Transparent communication and regulatory compliance help mitigate concern. Nevertheless, physical energy systems reintroduce visibility into operations that were previously abstract. This visibility demands thoughtful engagement rather than avoidance.

Operational Continuity Beyond Grid Dependency

One of the central motivations for fuel integration lies in autonomy. Fuel infrastructure inside digital campuses enables sustained operation independent of immediate grid conditions. This capability reframes continuity planning. Resilience is no longer defined solely by redundancy but by self-sufficiency. Fuel becomes a strategic buffer rather than an emergency fallback.

However, autonomy introduces responsibility. Stored energy must be managed, replenished, and safeguarded. Continuity planning therefore extends into supply chain coordination and on-site stewardship. These considerations expand the operational horizon beyond facility boundaries. Digital campuses become energy actors rather than passive consumers.

The presence of fuel systems reshapes workforce composition within digital campuses. Roles once focused exclusively on IT and electrical maintenance must adapt. Mechanical, chemical, and safety expertise regain relevance. Cross-training becomes essential to bridge disciplinary gaps. Workforce planning thus evolves alongside infrastructure design.

Organizational structures must support this diversification. Silos between facilities, operations, and safety functions become less tenable. Collaboration across domains ensures coherent decision-making. Fuel infrastructure inside digital campuses therefore influences corporate governance as much as technical architecture.

Maintenance Regimes and Lifecycle Awareness

Fuel systems impose maintenance demands distinct from electrical equipment. Inspection cycles, material degradation, and component wear follow different patterns. Lifecycle awareness becomes critical to prevent latent failures. Maintenance planning must account for both routine servicing and exceptional interventions. This discipline reinforces long-term operational thinking.

Documentation plays a central role in sustaining these regimes. Records of inspections, incidents, and modifications form institutional memory. Unlike purely digital configurations, fuel systems penalize neglect over time. Continuous attention ensures that stored energy remains an asset rather than a liability.

The reappearance of fuel systems challenges minimalist design philosophies. Abstraction gives way to explicit acknowledgment of physical processes. Designers must reconcile digital efficiency with mechanical presence. This reconciliation fosters more holistic thinking about infrastructure. Complexity is managed rather than eliminated.

Architectural expression also evolves in response. Buildings must communicate safety and functionality without undermining digital purpose. Material choices, circulation paths, and visual cues reflect this duality. Fuel infrastructure inside digital campuses thus leaves an imprint on form as well as function.

Institutional Memory and Industry Learning

As fuel systems reenter digital environments, institutional memory must be rebuilt. Lessons from industrial energy sectors provide valuable reference points. Knowledge transfer becomes a strategic exercise. Avoiding past mistakes requires deliberate engagement with established practices. This learning process tempers innovation with experience.

Industry forums and standards bodies play a coordinating role. Shared frameworks help normalize fuel integration practices. Collective learning reduces fragmentation across implementations. Fuel infrastructure inside digital campuses thus benefits from communal rather than isolated evolution.

The reintroduction of fuel systems compels organizations to reassess governance models governing digital campuses. Energy decisions can no longer be delegated solely to facilities teams operating at the periphery. Executive oversight becomes more involved as fuel introduces material risk and regulatory exposure. Governance frameworks must therefore integrate operational, legal, and safety considerations. This integration elevates energy infrastructure to board-level visibility.

Decision-making authority must also be clarified. Fuel-related incidents demand rapid, coordinated responses that cut across organizational hierarchies. Ambiguity in responsibility can exacerbate operational disruption. Clear escalation paths and defined ownership reduce uncertainty. Governance maturity becomes a prerequisite for safe fuel integration.

Insurance, Liability, and Risk Transfer

Fuel infrastructure inside digital campuses reshapes insurance relationships. Underwriters evaluate physical energy systems differently from electrical redundancy. Liability considerations extend beyond equipment failure to environmental and safety outcomes. Coverage terms may reflect this expanded risk profile. Insurance engagement therefore becomes more nuanced and continuous.

Risk transfer mechanisms must align with operational realities. Traditional policies designed for IT environments may prove insufficient. Insurers often require evidence of robust safety management and compliance regimes. Documentation and audits support these requirements. Fuel presence thus influences financial planning alongside technical design.

Fuel systems create persistent interfaces with external supply chains. Deliveries, replenishment schedules, and quality assurance processes extend operational boundaries. Dependence on upstream partners introduces coordination challenges. Stewardship of fuel resources becomes an ongoing responsibility rather than a one-time procurement exercise.

These interfaces demand transparency and reliability. Contractual arrangements must address continuity and safety expectations. Disruptions upstream can cascade into campus operations if not anticipated. Supply chain resilience therefore becomes intertwined with on-site fuel management.

Standards Development and Industry Alignment

As fuel integration accelerates, standards bodies respond with updated frameworks. Codes governing storage, handling, and integration evolve to reflect new use cases. Alignment with these standards ensures consistency across implementations. Participation in standards development allows operators to shape emerging norms.

Standardization also facilitates interoperability. Shared terminology and requirements reduce ambiguity among designers, operators, and regulators. Fuel infrastructure inside digital campuses benefits from this harmonization. Collective adherence accelerates safe adoption without stifling innovation.

The presence of fuel systems influences organizational culture. Teams accustomed to abstract digital workflows confront tangible physical processes. This encounter fosters renewed respect for material constraints. Awareness of physical risk encourages disciplined operational behavior. Culture adapts alongside infrastructure. Communication practices also evolve. Safety briefings, cross-functional meetings, and shared responsibility become normalized. The separation between digital and physical domains narrows. Fuel infrastructure inside digital campuses thus contributes to a more integrated operational mindset.

Emergency planning must account for fuel-specific scenarios. Response protocols differ from those addressing electrical outages alone. Evacuation, containment, and communication strategies require revision. Preparedness becomes multidimensional rather than singularly focused. Training exercises reinforce readiness. Simulated incidents help teams internalize procedures. Coordination with local authorities strengthens external response alignment. Fuel presence ensures that emergency preparedness remains an active discipline.

Architectural Permanence and Strategic Commitment

Fuel systems introduce permanence into campus architecture. Unlike modular IT components, storage vessels and safety zones resist rapid reconfiguration. Their installation signals long-term strategic commitment. Decisions made early influence operational trajectories for decades.

This permanence encourages deliberate planning. Short-term expediency yields to lifecycle consideration. Fuel infrastructure inside digital campuses thus anchors digital ambition in physical reality. Strategy becomes embodied rather than abstract.

Sustaining fuel systems requires institutional memory. Personnel turnover can erode hard-earned expertise. Knowledge management practices preserve operational insight. Documentation and mentorship support continuity.

Organizational memory mitigates risk over time. Lessons learned from minor incidents prevent escalation. Fuel infrastructure inside digital campuses therefore rewards organizations that value continuity. Experience becomes a strategic asset.

Strategic Signaling Within the Industry

The reappearance of fuel systems sends a signal beyond individual campuses. Industry observers interpret these moves as indicators of long-term positioning. Organizations adopting fuel infrastructure inside digital campuses communicate a willingness to engage with physical complexity. This signal differentiates strategic posture rather than technological capability alone. Market perception evolves accordingly.

Such signaling influences peer behavior. Visibility of fuel integration normalizes practices previously considered atypical. Competitive dynamics shift as resilience narratives expand. Strategic signaling thus accelerates diffusion without formal mandates.

Fuel infrastructure demands extended investment horizons. Capital allocation decisions must account for long-lived assets. Short-cycle optimization gives way to durable planning. Financial discipline aligns with infrastructural permanence.

This alignment influences prioritization. Investments favor robustness over incremental efficiency. Fuel infrastructure inside digital campuses embodies this philosophy. Strategic patience becomes a defining characteristic.

Institutional Trust and Stakeholder Confidence

Stakeholders evaluate how organizations manage physical risk. Fuel systems test governance maturity and transparency. Successful integration builds institutional trust. Confidence extends beyond immediate operations.

Trust also affects partnerships. Regulators, suppliers, and communities respond to demonstrated competence. Fuel infrastructure inside digital campuses thus influences relational capital. Reputation evolves through operational behavior. Resilience emerges as a guiding ethos rather than a checklist. Fuel integration reinforces this orientation. Systems are designed to endure variability. Adaptability becomes embedded in infrastructure choices.

This ethos shapes organizational identity. Resilience informs culture, governance, and planning. Fuel infrastructure inside digital campuses exemplifies commitment to continuity. Strategy aligns with material reality.

Digital industries long favored abstraction. Fuel systems reintroduce materiality into strategic thought. Physical constraints regain legitimacy. Balance replaces avoidance. This rebalancing enriches design discourse. Engineers and executives engage with tangible systems. Fuel infrastructure inside digital campuses grounds digital ambition. Thought becomes embodied.

Adopting fuel systems reflects technical confidence. Organizations assert capability to manage complexity responsibly. Identity evolves from consumer to steward. Confidence becomes visible through infrastructure. This identity influences recruitment and retention. Skilled professionals gravitate toward mature operational environments. Fuel infrastructure inside digital campuses signals seriousness of purpose. Talent alignment follows.

Temporal Perspective and Strategic Patience

Fuel systems encourage longer temporal perspectives. Decisions account for decades rather than quarters. Strategic patience becomes operationalized. Infrastructure embodies foresight. This patience stabilizes planning cycles. Organizations resist reactive shifts. Fuel infrastructure inside digital campuses anchors continuity. Time horizons expand.

Industry Narratives and Future Orientation

Narratives surrounding digital infrastructure evolve. Fuel integration reframes discussions of progress. Innovation includes revisiting proven principles. Future orientation blends novelty with continuity. These narratives influence policy and investment. Discourse becomes more nuanced. Fuel infrastructure inside digital campuses exemplifies pragmatic evolution. Vision remains grounded.

Fuel systems introduce learning curves that unfold over extended operational timelines. Early stages emphasize compliance and basic functionality. Over time, organizations develop a nuanced understanding of system behavior. Operational maturity emerges through exposure rather than theoretical preparation. This progression reinforces the importance of institutional patience.

Learning curves also influence decision confidence. Familiarity reduces hesitation in operational adjustments. Teams gain intuition about fuel behavior under varying conditions. Fuel infrastructure inside digital campuses therefore rewards experiential learning. Knowledge accumulates through practice rather than abstraction.

Interoperability Between Legacy and Emerging Systems

Digital campuses rarely operate on blank slates. Fuel systems must coexist with legacy electrical and mechanical infrastructure. Interoperability challenges arise at technical and procedural levels. Integration strategies must respect existing constraints. Harmonization becomes a central design objective.

Legacy systems carry embedded assumptions that may conflict with fuel integration. Resolving these tensions requires careful modification rather than wholesale replacement. Incremental adaptation preserves operational stability. Fuel infrastructure inside digital campuses thus evolves through negotiation with the past.

Comprehensive documentation underpins safe fuel operations. Schematics, procedures, and records form a knowledge backbone. Documentation supports training and compliance. Its strategic value extends beyond administrative necessity.

Well-maintained records enable continuity across personnel changes. Institutional memory remains intact despite turnover. Fuel infrastructure inside digital campuses depends on this continuity. Documentation transforms experience into organizational capital.

External Benchmarking and Peer Comparison

Organizations observe peers adopting fuel systems. Benchmarking informs internal evaluation. Comparative analysis focuses on governance and integration approaches rather than performance metrics. Learning occurs through observation and dialogue.

Peer comparison also shapes expectations. Practices gain legitimacy through repetition. Fuel infrastructure inside digital campuses becomes normalized through collective adoption. Industry standards emerge organically.

Fuel integration raises ethical considerations. Stewardship of energy resources carries moral weight. Decisions affect communities and environments. Ethical framing complements technical analysis. Organizations articulate values through infrastructure choices. Responsible management reinforces ethical commitments. Fuel infrastructure inside digital campuses embodies accountability. Ethics become operationalized.

Communication Strategies and Transparency

Clear communication supports fuel integration. Stakeholders require accurate information. Transparency builds trust and mitigates concern. Messaging must balance technical precision with accessibility.

Internal communication aligns teams around shared understanding. External communication addresses regulatory and community audiences. Fuel infrastructure inside digital campuses benefits from proactive engagement. Silence invites speculation.

Operational experience informs design refinement. Feedback loops enable continuous improvement. Lessons learned translate into updated procedures and layouts. Iteration strengthens resilience. Design refinement reflects humility. Assumptions yield to evidence. Fuel infrastructure inside digital campuses evolves through adjustment rather than rigidity. Adaptation sustains relevance.

Temporal Stability and Infrastructure Longevity

Fuel systems emphasize longevity. Assets are expected to endure. Temporal stability becomes a planning principle. Infrastructure decisions resist short-term volatility.

Longevity influences maintenance and governance. Long-lived systems demand sustained attention. Fuel infrastructure inside digital campuses aligns operations with enduring responsibility. Time becomes an ally rather than a constraint

Digital operations value speed and responsiveness. Fuel systems impose deliberation. Reconciling these tempos challenges organizational reflexes. Balance emerges through disciplined processes. Deliberation enhances safety and reliability. Speed remains valuable within defined boundaries. Fuel infrastructure inside digital campuses harmonizes urgency with caution. Operational rhythm matures.

The Quiet Permanence of Fuel’s Return

Fuel systems reenter digital campuses without spectacle. Their presence grows through necessity rather than proclamation. Permanence emerges quietly. Infrastructure reshapes assumptions over time.This quiet return reflects structural change. Digital growth intersects with physical reality. Fuel infrastructure inside digital campuses signifies recalibration. Progress becomes grounded.