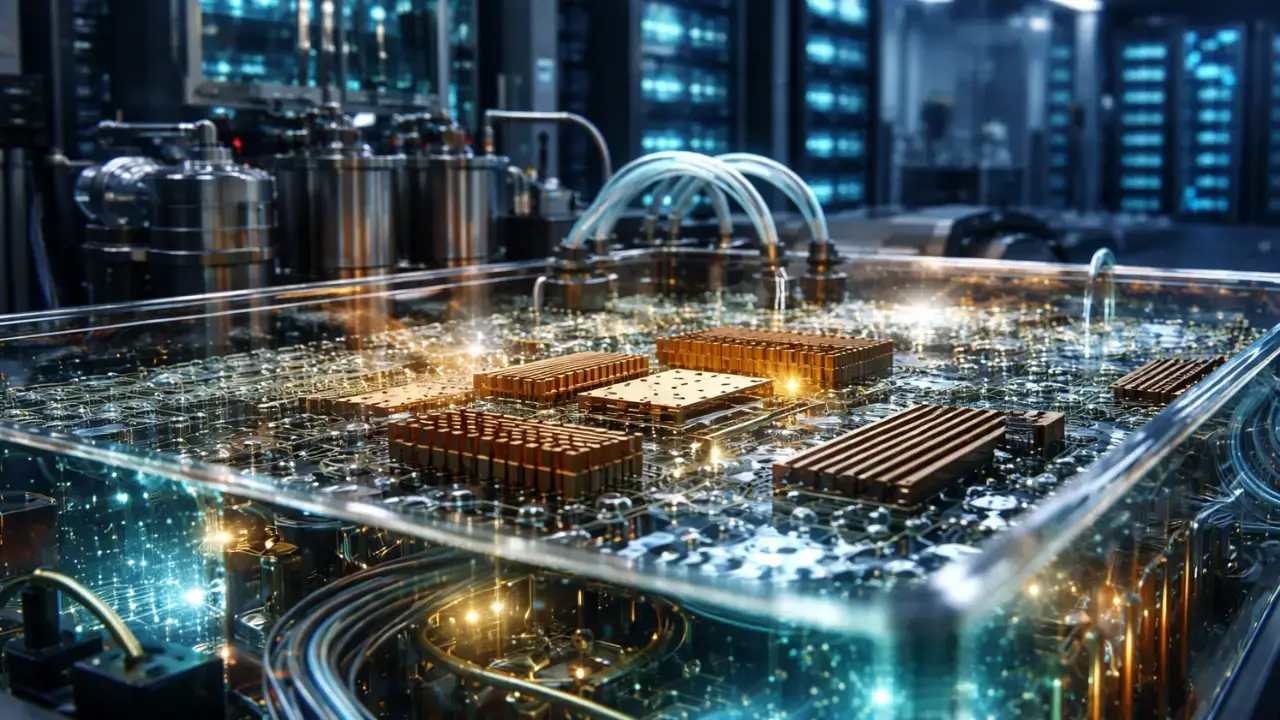

The future of AI infrastructure no longer echoes only with the mechanical rush of air coursing through rigid server aisles, because a subtler yet far more consequential transformation now circulates through the core of modern compute environments. What once revolved around optimizing airflow geometry and maximizing rack density has evolved into a deeper reconsideration of thermal philosophy, driven by liquid immersion and advanced dielectric systems. As artificial intelligence workloads intensify and silicon density accelerates beyond conventional thresholds, heat no longer lingers as a background engineering concern but rises to become the central architectural determinant.

Infrastructure strategists consequently understand that cooling is not merely a supporting utility appended to compute, but a defining force that influences how compute platforms are conceived, deployed, and sustained. This evolution represents more than incremental innovation, because it reconceptualizes infrastructure as a cohesive fluid ecosystem in which chemistry, materials science, and durability converge. Within this submerged architecture, dielectric fluid ecosystems stand not at the margins of operations but at the very heart of long-term resilience and systemic integrity.

Fluid-based cooling strategies do not simply replace air with liquid, because they introduce an entirely different thermodynamic and materials-driven logic into data center design. Air systems depend on large volumes and pressure differentials, whereas immersion systems rely on direct contact between engineered fluids and energized components. That direct contact elevates chemical stability, dielectric strength, and material compatibility from secondary considerations to strategic priorities. Consequently, infrastructure planners must think beyond kilowatts per rack and instead analyze molecular behavior, surface chemistry, and fluid aging pathways. Every design decision, from solder composition to gasket selection, interacts with the fluid environment in measurable ways. As a result, the concept of infrastructure resilience now extends into chemistry labs as much as into server halls.

From Airflow to Immersion: Why Fluids Are Reshaping Infrastructure Thinking

The architectural shift from airflow management to immersion cooling reflects a broader philosophical transformation in how operators define efficiency and control. Traditional air-cooled facilities relied on containment strategies, raised floors, and intricate ductwork to guide temperature gradients across hardware arrays. Immersion systems instead eliminate much of that spatial choreography and embed thermal exchange directly at the component level. This direct thermal pathway reduces temperature differentials across chips and boards, which stabilizes performance envelopes under sustained AI workloads. Moreover, designers can rethink rack density constraints because fluids remove heat more efficiently than air in comparable conditions. Consequently, immersion cooling reframes infrastructure from a mechanical airflow challenge into a fluid-chemistry engineering discipline.

Operators who adopt immersion also reconsider physical layout, maintenance philosophy, and risk modeling practices. Air systems separate electronics from cooling media through physical barriers, whereas immersion systems deliberately dissolve that boundary. Such integration requires confidence in dielectric integrity and long-term chemical stability under electrical stress. Therefore, facility managers collaborate more closely with chemists and materials scientists during procurement and design phases. This collaboration reshapes vendor ecosystems, because coolant suppliers now influence reliability projections as directly as hardware manufacturers. In this new framework, dielectric fluid ecosystems underpin strategic planning rather than simply filling tanks.

Infrastructure Density and Thermal Determinism

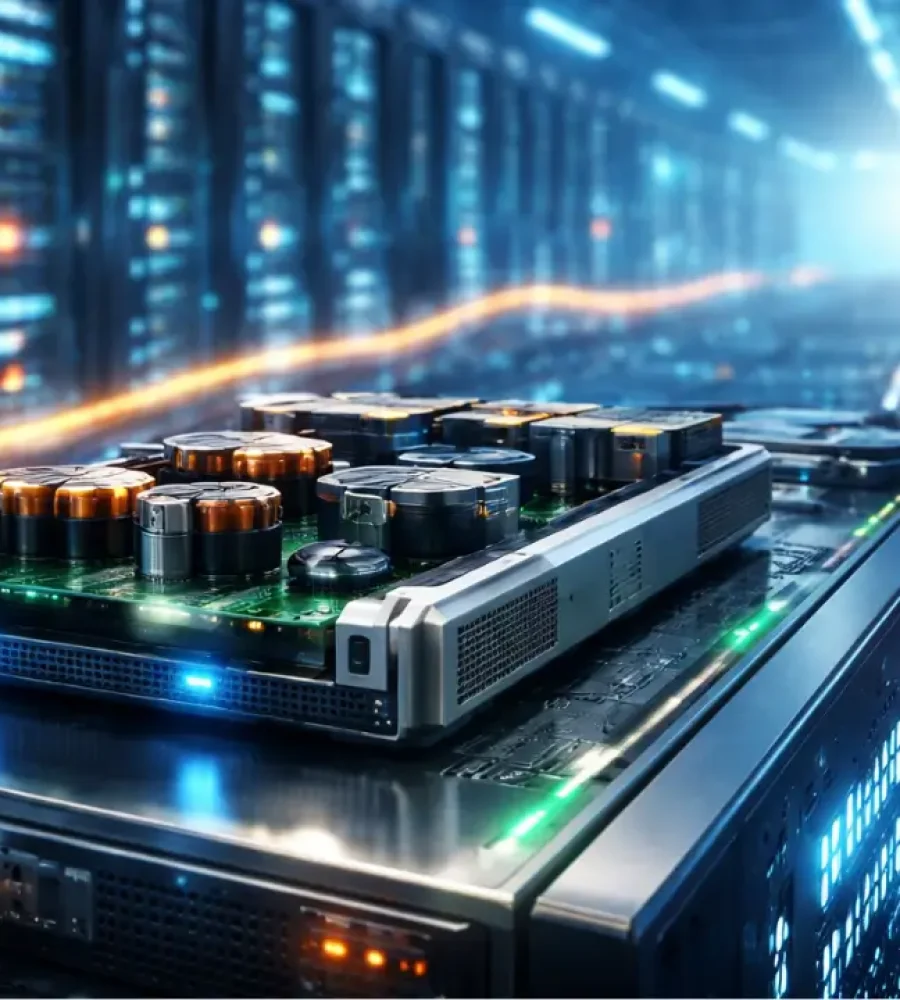

AI-era data centers pursue unprecedented compute density, and thermal determinism increasingly governs their scalability. As chip architectures concentrate more transistors into compact footprints, localized heat flux rises sharply and challenges traditional convection models. Immersion cooling addresses this constraint by enabling consistent temperature control across hotspots without relying on high-velocity airflow. Engineers can thus maintain narrower temperature bands, which protects silicon longevity and stabilizes computational output. This predictability strengthens infrastructure planning because thermal variables no longer fluctuate as widely under peak loads. Consequently, fluid systems support not only cooling but also deterministic performance engineering.

Immersion environments also encourage modularity in infrastructure deployment. Instead of building vast air-handling capacity in advance, operators can scale fluid tanks in alignment with compute expansion. This modular approach aligns capital expenditure with workload growth, which supports more agile deployment strategies. Furthermore, fluid systems often reduce acoustic and mechanical complexity, thereby simplifying facility retrofits in urban or edge locations. As immersion gains acceptance, architects integrate fluid pathways into building design from inception rather than as afterthoughts. Through this lens, dielectric fluid ecosystems become structural elements of data center blueprints.

The Chemistry of Dielectric Fluids: Beyond Simple Heat Transfer

Dielectric fluids function as more than passive heat carriers, because their molecular architecture determines electrical insulation, oxidation resistance, and long-term reliability. Engineers evaluate dielectric strength to ensure that energized components remain electrically isolated even when fully submerged. Molecular stability under thermal cycling plays an equally critical role, since AI workloads generate sustained high temperatures that stress chemical bonds. If a fluid oxidizes or decomposes under such stress, it can form acids or particulates that compromise hardware integrity. Therefore, formulation chemists design dielectric fluids with stable molecular backbones and carefully selected additives. These chemical design choices directly influence the operational lifespan of both the coolant and the hardware it protects.

Oxidation behavior represents a particularly decisive parameter in immersion environments. When fluids encounter oxygen at elevated temperatures, reactive pathways can initiate degradation that alters viscosity and dielectric properties. Manufacturers counteract these reactions by incorporating antioxidant packages and refining base stocks to reduce impurity levels. However, additive interactions must remain compatible with metals, polymers, and solder materials inside submerged systems. Consequently, chemical engineering teams perform accelerated aging tests to simulate years of exposure within compressed timelines. Through such testing, dielectric fluid ecosystems evolve from theoretical constructs into validated reliability frameworks.

The dielectric constant and breakdown voltage of a fluid also govern system safety and performance margins. High dielectric strength ensures that electrical arcing does not occur even under voltage fluctuations or transient loads. Meanwhile, low electrical conductivity prevents stray currents that could degrade component interfaces over time. Engineers must therefore balance thermal conductivity, viscosity, and dielectric performance within a single formulation. Trade-offs inevitably arise, because enhancing one property may influence another in subtle ways. Thus, coolant innovation demands holistic chemical optimization rather than single-parameter improvement.

Synthetic vs. Natural Fluids: Engineering Trade-offs in Modern Cooling

Modern immersion cooling relies on diverse fluid chemistries, including synthetic hydrocarbons, fluorinated liquids, and bio-based formulations. Synthetic hydrocarbons often deliver strong thermal performance and favorable dielectric properties, yet they require careful oxidation management. Fluorinated fluids provide exceptional dielectric strength and chemical inertness, although they can present environmental and cost considerations. Bio-based fluids attract interest for their renewable sourcing and biodegradability, yet they must meet stringent stability and compatibility requirements. Engineers evaluate each option against performance targets, regulatory constraints, and sustainability goals. Therefore, fluid selection becomes a multi-dimensional engineering decision rather than a simple procurement exercise.

Formulation strategies further differentiate these categories in real-world deployment. Synthetic fluids may incorporate tailored additive packages that enhance oxidation resistance or metal passivation. Fluorinated liquids often rely on intrinsic chemical stability, which reduces the need for complex additive systems. Bio-based fluids demand rigorous refinement processes to eliminate impurities that could compromise dielectric strength. In each case, compatibility testing with seals, gaskets, and printed circuit boards determines long-term viability. Through such comparative analysis, operators construct dielectric fluid ecosystems aligned with both technical and environmental priorities.

Environmental considerations increasingly shape coolant innovation trajectories. Regulatory scrutiny around global warming potential and chemical persistence influences formulation research and market adoption. Consequently, manufacturers invest in next-generation molecules that balance performance with reduced environmental impact. Infrastructure planners also assess lifecycle emissions associated with production, transport, and disposal of coolant volumes. These broader considerations elevate fluid choice into strategic sustainability conversations. As the industry evolves, synthetic and natural fluids compete and coexist within a complex matrix of engineering trade-offs.

Material Compatibility: Metals, Polymers, and Seal Integrity

Material compatibility defines whether an immersion system thrives for a decade or struggles within a few operational cycles. When dielectric fluids interact with copper traces, aluminum heat spreaders, and steel fasteners, subtle electrochemical dynamics can emerge. Engineers therefore conduct corrosion testing under elevated temperatures to detect galvanic interactions before deployment. Even trace impurities in a fluid may accelerate oxidation on exposed metal surfaces if left unmanaged. Designers mitigate such risks through inhibitor chemistry and careful alloy selection across hardware assemblies. Consequently, dielectric fluid ecosystems demand synchronized decisions between coolant formulation and component metallurgy.

Polymers and elastomers introduce another dimension of complexity in submerged environments. O-rings, gaskets, cable jackets, and connector housings often rely on materials such as EPDM, silicone, or fluorocarbon elastomers. When immersed, these materials may swell, harden, or leach plasticizers depending on fluid polarity and molecular structure. Swelling alters compression set behavior in seals, which can compromise enclosure integrity over extended service intervals. Manufacturers therefore perform immersion compatibility tests that measure dimensional stability and tensile strength retention. Through such validation protocols, operators safeguard long-term seal integrity within dielectric fluid ecosystems.

Adhesives and conformal coatings also respond differently when submerged in dielectric liquids. Some coatings resist fluid penetration and preserve dielectric isolation on printed circuit boards. Others may soften or delaminate under sustained immersion, particularly if exposed to thermal cycling. Engineers analyze adhesion strength, microcracking tendencies, and chemical resistance during product qualification. These assessments ensure that protective layers maintain electrical isolation and structural cohesion across operational lifespans. By integrating coating science into immersion design, infrastructure teams strengthen compatibility at both macro and micro scales.

Fluid Aging and Degradation Pathways

Every dielectric fluid ages, yet the mechanisms of degradation vary according to chemistry and operating environment. Thermal stress accelerates molecular bond scission in susceptible compounds, which may generate byproducts that alter viscosity and dielectric strength. Exposure to oxygen further compounds degradation through oxidative chain reactions that produce acids or sludge-like residues. These changes can influence heat transfer efficiency and electrical insulation capacity over time. Therefore, operators monitor key indicators such as acid number, color change, and dielectric breakdown voltage. Through systematic analysis, teams anticipate performance shifts before they affect hardware reliability.

Contaminants introduced during maintenance or hardware replacement can amplify aging pathways. Even small amounts of water ingress may reduce dielectric strength and promote corrosion on exposed metals. Particulate matter generated by component wear can accumulate and alter fluid clarity or flow characteristics. Chemical impurities from manufacturing residues may interact with additives and trigger unintended reactions. Consequently, immersion systems rely on rigorous cleanliness protocols during installation and servicing. Within dielectric fluid ecosystems, contamination control directly supports predictable aging trajectories.

Thermal cycling imposes repeated expansion and contraction stresses on both fluid molecules and hardware materials. Over extended intervals, such cycling can shift viscosity profiles and influence convective behavior within immersion tanks. Engineers design fluid formulations to maintain stable rheological properties across expected temperature ranges. Meanwhile, accelerated life testing simulates multi-year operational conditions within compressed laboratory timelines. These simulations reveal degradation trends that inform maintenance schedules and fluid replacement strategies. Through proactive aging management, operators preserve reliability in submerged infrastructures.

Contamination Control: Particulates, Moisture, and Chemical Impurities

Immersion stability depends heavily on maintaining fluid purity throughout its service life. Particulates may originate from manufacturing residues, solder fragments, or wear particles generated during component handling. If allowed to circulate freely, these particles can settle on board surfaces and influence localized heat transfer. Filtration systems therefore operate continuously or periodically to remove suspended solids from immersion tanks. Engineers specify filter pore sizes according to hardware tolerances and fluid viscosity. Through structured filtration strategies, dielectric fluid ecosystems sustain thermal consistency and electrical insulation.

Moisture presents a particularly sensitive contamination vector in dielectric systems. Although many fluids exhibit low water solubility, even minimal dissolved moisture can depress dielectric breakdown voltage. In high-voltage or high-density AI clusters, this reduction may narrow safety margins. Operators therefore integrate moisture monitoring sensors and desiccant-based drying systems into fluid management loops. Routine sampling and laboratory analysis confirm compliance with predefined moisture thresholds. Such vigilance ensures that immersion environments maintain robust electrical isolation over time.

Chemical impurities from external sources can also undermine fluid performance. Cleaning solvents, residual flux, or incompatible lubricants may enter tanks during servicing if protocols lapse. Once introduced, these chemicals can alter additive balance or accelerate oxidation reactions. Preventive training programs and strict procedural controls reduce such cross-contamination risks. Moreover, documented chain-of-custody practices for fluid handling strengthen accountability across teams. Within dielectric fluid ecosystems, operational discipline proves as vital as chemical formulation.

Surface Interactions: Coatings, Finishes, and Micro-Scale Dynamics

Surface chemistry governs how fluids interact with the microscopic landscapes of electronic assemblies. Printed circuit boards often feature finishes such as ENIG, immersion silver, or tin coatings, each with distinct chemical behavior. When submerged, these finishes encounter continuous exposure to dielectric molecules under thermal stress. Engineers evaluate whether any surface reactions produce discoloration, corrosion, or altered solder joint integrity. Even minor chemical interactions can influence long-term electrical continuity across micro-scale pathways. Consequently, compatibility testing extends beyond bulk materials into surface-level dynamics.

Solder alloys used in modern electronics also merit scrutiny within immersion systems. Lead-free formulations containing tin, silver, and copper may respond differently to prolonged fluid exposure compared to legacy alloys. Although dielectric fluids typically avoid aggressive chemical reactions, trace additives or degradation products can influence solder surfaces over time. Laboratory immersion studies measure joint strength retention and inspect for microstructural changes. These evaluations protect against latent failure modes that might otherwise emerge years into deployment. By addressing solder-fluid interactions early, designers reinforce infrastructure durability.

Micro-scale flow patterns inside immersion tanks further shape surface behavior. Fluid circulation distributes heat uniformly, yet localized stagnation zones may develop near dense component clusters. In such areas, temperature gradients can influence chemical reaction rates at material interfaces. Engineers therefore model flow dynamics to ensure consistent thermal and chemical conditions throughout the tank volume. Computational simulations guide pump placement and baffle design to prevent dead zones. Through integrated fluid dynamics analysis, dielectric fluid ecosystems maintain surface stability across complex hardware geometries.

Fluid Handling and Lifecycle Management

Handling dielectric fluids requires disciplined logistical and environmental stewardship. Storage containers must protect against moisture ingress, ultraviolet exposure, and particulate contamination. During transport, sealed systems prevent cross-contamination and preserve additive balance. Once delivered, operators transfer fluids into tanks using clean, dedicated equipment to maintain purity standards. Documentation accompanies each batch to ensure traceability and compliance with quality benchmarks. Through structured handling protocols, dielectric fluid ecosystems retain their engineered properties from factory to facility.

Lifecycle management extends beyond initial deployment into recycling and regeneration practices. Over time, operators may filter and recondition fluids to restore performance characteristics without full replacement. Analytical laboratories assess viscosity, acid number, and dielectric strength before approving reuse. If regeneration proves insufficient, environmentally responsible disposal pathways mitigate ecological impact. Manufacturers increasingly design fluids with recyclability in mind to support circular economy principles. Therefore, lifecycle planning strengthens both operational resilience and sustainability alignment.

Inventory management also influences infrastructure resilience. Operators maintain contingency reserves to address unexpected losses or maintenance requirements. Digital monitoring systems track fluid volume, quality metrics, and service intervals across distributed sites. Such data-driven oversight supports proactive decision-making and reduces downtime risk. Strategic sourcing agreements with chemical suppliers further enhance supply continuity. Within dielectric fluid ecosystems, lifecycle governance anchors long-term reliability.

Safety Frameworks: Fire, Toxicity, and Environmental Risk Considerations

Safety considerations guide coolant selection as decisively as thermal performance. Flash point and fire resistance determine how fluids behave under extreme fault conditions. Many dielectric fluids offer high flash points, which reduce ignition risk relative to certain traditional coolants. Nonetheless, operators implement fire detection and suppression systems aligned with fluid characteristics. Safety data sheets provide guidance on handling procedures and exposure controls. Through comprehensive risk assessment, dielectric fluid ecosystems align with rigorous safety standards.

Toxicity and occupational health factors also influence fluid deployment strategies. Although most immersion coolants aim for low toxicity profiles, personnel training ensures safe handling during maintenance. Ventilation systems address any potential vapor accumulation in enclosed spaces. Environmental impact assessments evaluate biodegradability and persistence in case of accidental release. Regulatory compliance frameworks differ across jurisdictions, requiring localized review and documentation. Consequently, safety governance integrates chemistry, operations, and policy considerations.

Environmental narratives increasingly shape public perception of large-scale AI infrastructure. Stakeholders scrutinize chemical usage alongside energy consumption metrics. Operators therefore communicate transparently about coolant composition, lifecycle management, and spill prevention measures. Responsible sourcing and disposal practices reinforce community trust. Moreover, collaborative research initiatives explore next-generation fluids with lower environmental footprints. Through proactive engagement, dielectric fluid ecosystems align with evolving environmental expectations.

Reliability Engineering in a Submerged World

Immersion cooling transforms reliability engineering from a largely mechanical discipline into a chemically integrated systems science. Traditional air-cooled hardware often failed due to fan wear, dust accumulation, or thermal cycling across uneven airflow zones. In submerged environments, mechanical airflow components disappear, yet fluid dynamics and chemical stability assume greater importance. Engineers now evaluate failure modes that include seal degradation, fluid contamination, and long-term material compatibility shifts. These variables demand cross-disciplinary analysis that bridges electrical engineering with materials chemistry. As a result, dielectric fluid ecosystems redefine reliability modeling across the infrastructure stack.

Hardware failure modes also evolve under immersion conditions. Without airborne particulates, boards experience less dust-related fouling and reduced electrostatic buildup. However, immersion introduces continuous contact between energized components and a chemically active medium. Designers therefore consider connector design, cable routing, and mechanical supports that operate effectively within fluid volumes. Component manufacturers increasingly validate products specifically for submerged deployment. Through such coordinated validation, operators reduce uncertainty and strengthen infrastructure dependability.

Predictive maintenance strategies adapt accordingly within submerged systems. Sensors monitor fluid temperature, dielectric strength, and particulate levels in real time to identify emerging risks. Data analytics platforms correlate fluid metrics with hardware performance indicators to detect anomalies early. Maintenance teams respond based on condition-based triggers rather than fixed schedules alone. This proactive approach reduces unplanned downtime and supports consistent AI workload delivery. Consequently, reliability engineering in immersion facilities integrates digital oversight with chemical intelligence.

Serviceability also acquires new design parameters in immersion-cooled environments. Technicians must lift and handle fluid-coated components while maintaining cleanliness and preventing contamination. Operators therefore design ergonomic tank access systems and controlled draining procedures. Clear documentation and standardized workflows reduce variability during hardware swaps. Training programs emphasize chemical safety alongside electrical best practices. Through disciplined operational design, dielectric fluid ecosystems sustain both safety and uptime.

Long-term infrastructure planning reflects the predictable thermal envelope immersion systems can maintain. Uniform temperature control reduces thermal expansion stress on solder joints and semiconductor packages. Lower temperature variance can extend component lifespans under sustained AI inference and training loads. Planners therefore align capital expenditure cycles with extended hardware service horizons. This alignment strengthens return-on-investment calculations and reduces premature refresh cycles. In submerged worlds, reliability becomes a chemically stabilized constant rather than a fluctuating variable.

Supply Chain Evolution: Coolant Innovation as Strategic Leverage

Coolant innovation increasingly influences strategic positioning across the AI infrastructure supply chain. Chemical manufacturers now collaborate directly with hardware vendors during early design phases. Joint development programs tailor dielectric formulations to specific server architectures and power densities. These collaborations shorten validation cycles and reduce integration friction during deployment. As a result, fluid suppliers move from peripheral roles into central strategic partnerships. Dielectric fluid ecosystems thus reshape supplier hierarchies within the broader data center economy.

Procurement strategies also adapt to reflect this deeper interdependence. Operators negotiate long-term agreements that secure fluid availability alongside server supply commitments. Such agreements mitigate risk in markets where demand for immersion-ready infrastructure grows rapidly. Quality assurance frameworks extend upstream to chemical production facilities to ensure consistency across batches. Traceability systems document additive compositions and testing results to preserve performance integrity. Through integrated sourcing models, organizations reinforce the resilience of their fluid ecosystems.

Innovation cycles accelerate as immersion adoption expands globally. Startups explore novel molecular structures that deliver enhanced thermal conductivity with lower environmental impact. Established chemical firms invest in advanced refining techniques and additive research to optimize oxidation resistance. Hardware manufacturers, in parallel, redesign boards and enclosures specifically for fluid compatibility. These parallel innovation tracks converge within pilot deployments that validate ecosystem coherence. Consequently, supply chain evolution reflects a synchronized march toward chemically informed infrastructure.

Geopolitical considerations further influence coolant sourcing and production strategies. Regions with strong chemical manufacturing capacity may gain leverage in supplying immersion-ready fluids. Trade policies, regulatory requirements, and transportation logistics shape global distribution networks. Operators diversify supplier bases to mitigate concentration risk and ensure continuity. Industry consortia often facilitate knowledge exchange and standardization across markets. Through coordinated evolution, dielectric fluid ecosystems achieve both technical and strategic resilience.

Fluid Ecosystems as the Foundation of Resilient AI Infrastructure

AI infrastructure now stands at a crossroads where thermodynamics, chemistry, and digital ambition intersect. Air once defined the boundaries of data center architecture, yet liquid immersion now redraws those boundaries with molecular precision. This transformation demands that operators view coolant not as consumable inventory but as engineered infrastructure. Dielectric fluid ecosystems integrate chemistry, material science, compatibility analysis, and lifecycle governance into a unified reliability framework. Each molecule circulating within an immersion tank contributes to performance stability and hardware longevity. Therefore, coolant innovation assumes architectural significance equal to processors and power systems.

The journey from airflow to immersion reveals a broader lesson about infrastructure evolution. When thermal density rises beyond traditional limits, incremental adjustments no longer suffice. Engineers must instead reconsider foundational assumptions about separation between electronics and environment. Immersion dissolves that separation and introduces a chemically mediated operating reality. This reality requires deliberate coordination among chemists, materials scientists, hardware designers, and facility operators. Through such collaboration, dielectric fluid ecosystems mature into resilient operational platforms.

Long-term resilience ultimately depends on disciplined lifecycle stewardship. Fluid aging analysis, contamination control, and compatibility validation protect infrastructure from gradual degradation. Safety governance and environmental accountability reinforce social license to operate at scale. Supply chain alignment ensures that innovation translates into dependable deployment. Reliability engineering frameworks adapt to submerged conditions without sacrificing uptime expectations. Collectively, these elements form a cohesive architecture anchored in chemical intelligence.

As AI workloads expand and computational intensity continues to grow, infrastructure must evolve with equal sophistication. Immersion cooling does not merely solve a heat problem, because it reframes the entire ecosystem in which computation occurs. Fluid chemistry, once peripheral to server design, now guides architectural decisions at the highest level. Organizations that understand and invest in dielectric fluid ecosystems will likely navigate density challenges with greater confidence. Those ecosystems, carefully engineered and responsibly managed, provide the stability required for sustained AI advancement. In this submerged era, resilience flows not from air currents but from molecules engineered for endurance.