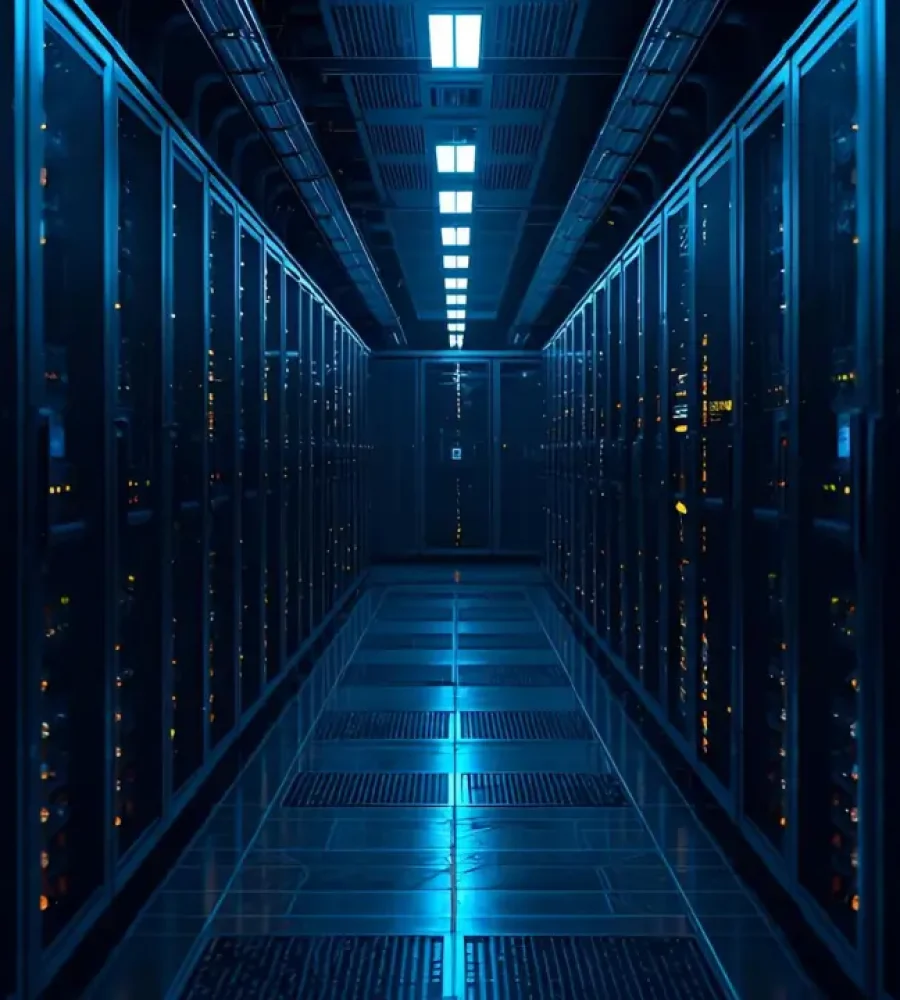

Fourier launched its Cold Plate Container Solution, a prefabricated containerized direct-to-chip system with an integrated chiller plant inside the module.

Delivering 0.5 MW per container with integrated, waterless direct-to-chip cooling, a benchmark-level density with simplified deployments and lower operating costs. This breakthrough sets a new milestone in scalable AI and HPC infrastructure.

Unlike conventional cold plate deployments that rely on external chilled-water plants or CDU loops, the Fourier cold plate container comes with a fully integrated chiller system. Servers can be racked and powered on immediately, without additional site infrastructure, enabling true plug-and-play deployment for AI training clusters and HPC workloads.

Sustainability

Operating with a sealed coolant loop that consumes virtually no water, the system removes dependence on municipal supply and chemical treatment. This allows reliable operation in water-scarce or high temperature regions while minimizing maintenance to periodic preventive servicing. Optimized cooling design further ensures lower PUE and minimized TCO.

Reliability

Each module supports up to 0.5 MW IT load, from 8×4090 training servers to single H100 deployments, and scales linearly to multi-megawatt campuses. Built with N+1 redundancy across pumps and fans, the system is engineered to meet Tier III standards with resilience approaching Tier IV, ensuring mission-critical availability and year-round continuous operation.

The Fourier Cold Plate Container represents a new era of prefabricated data center infrastructure combining density, efficiency, and sustainability in a single solution that redefines how AI and HPC clusters are deployed globally.