As semiconductors become inseparable from AI, energy systems, defense platforms and industrial automation, the pressure on chip manufacturing is no longer just about capacity, it is about reliability, localization and intelligence at scale. Against this backdrop, Siemens and GlobalFoundries (GF) are deepening their collaboration to embed AI-driven automation directly into the heart of semiconductor manufacturing.

Under a newly signed memorandum of understanding, the two companies are aligning their strengths across fab automation, electrification, digital software and lifecycle management. The focus is clear: use advanced AI-enabled software, sensors and real-time control systems to make chip production more efficient, secure and resilient, starting with GF’s own fabs, and extending outward to other advanced industries.

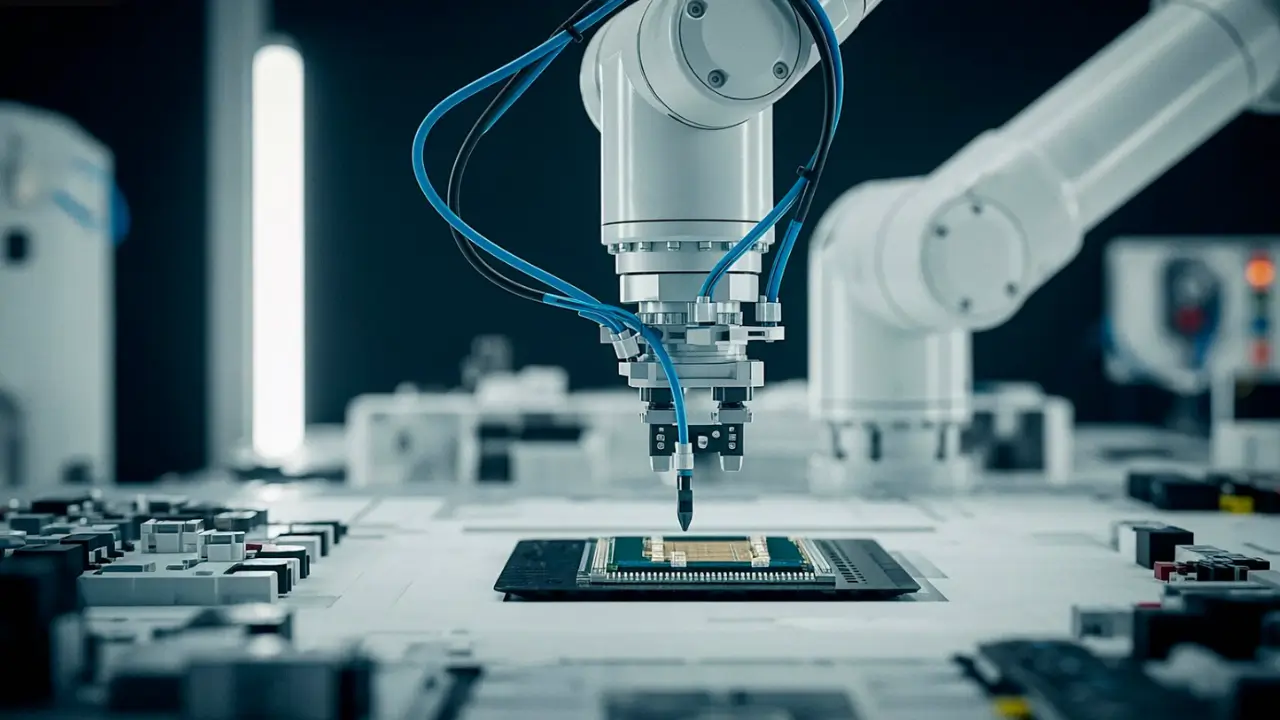

At the core of the collaboration is fab automation. By combining centralized automation with predictive maintenance, Siemens and GF aim to increase equipment availability and operational efficiency in semiconductor fabrication. The intent is not limited to incremental gains. Both companies plan to develop and deploy new solutions internally, using their own operations as proving grounds before translating those capabilities into broader industrial offerings.

The timing reflects wider industry pressures. Demand for semiconductors, particularly those supporting AI workloads, autonomous systems, connectivity and energy infrastructure has reached levels where manufacturing reliability and supply-chain security are strategic concerns. Export controls, geopolitical concentration and surging compute needs have exposed vulnerabilities that software-driven manufacturing intelligence is increasingly expected to address.

For Siemens, the partnership reinforces its push to connect AI, automation and digital twins across the full semiconductor lifecycle, from chip design and manufacturing to product lifecycle management. Its industrial software, electrification technologies and automation platforms are positioned as the connective tissue that enables seamless coordination across complex production environments.

For GlobalFoundries, the collaboration aligns with its emphasis on secure, locally manufactured semiconductors. As one of the world’s leading foundries, with manufacturing operations across the US, Europe and Asia, including Europe’s largest semiconductor site in Dresden, GF is positioning AI-enabled manufacturing as a way to scale differentiated, energy-efficient and secure chips for next-generation applications.

GF’s process technology and design capabilities, combined with MIPS’ RISC-V processor IP, are also expected to support Siemens’ broader ambition to enable autonomous platforms and physical AI at scale. The collaboration suggests a shift from viewing AI solely as a product feature to treating it as a manufacturing enabler, one that determines how fast, how securely and how locally chips can be produced.

In an industry where silicon is both an economic foundation and a geopolitical asset, the Siemens–GlobalFoundries partnership signals a growing consensus: the future of semiconductor competitiveness will be shaped as much by AI-driven manufacturing intelligence as by chip architectures themselves.